Diaphragm Pumps - Questions and Answers

What is a diaphragm pump?

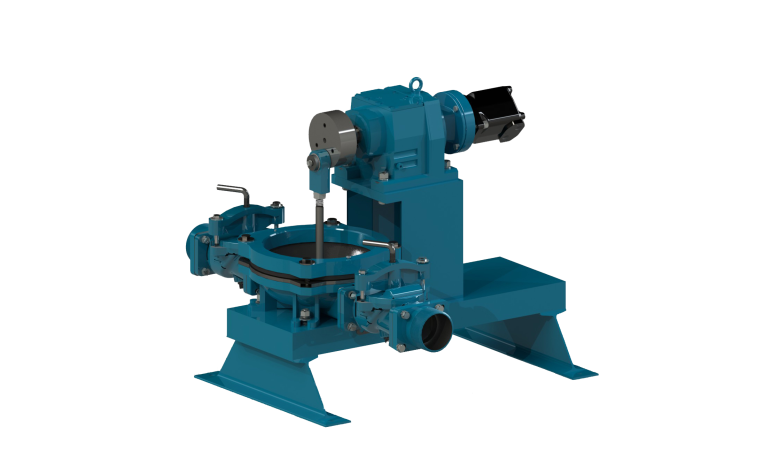

A diaphragm pump (also called a membrane pump) is a type of positive displacement pump that uses suction to transfer liquids. The flow of liquid is controlled with either a flapper or a ball valve and driven by the reciprocating action of the diaphragms. As the diaphragms move back and forth, they create negative air pressure in the pump chambers, drawing in and expelling liquid in a consistent pattern.

Because diaphragm pumps do not use an impeller, they are very versatile. If you have an air operated diaphragm pump (AOD) cases, you will require an air compressor to operate a the pump. If you have an electric or engine driven pump you will require either 120V, 460V or gas, diesel, propane or natural gas. Unlike centrifugal pumps, diaphragm pumps are self-priming and can withstand significant variations in volume, flow rate, and viscosity

Learn more from our video

What types of diaphragm pumps are available?

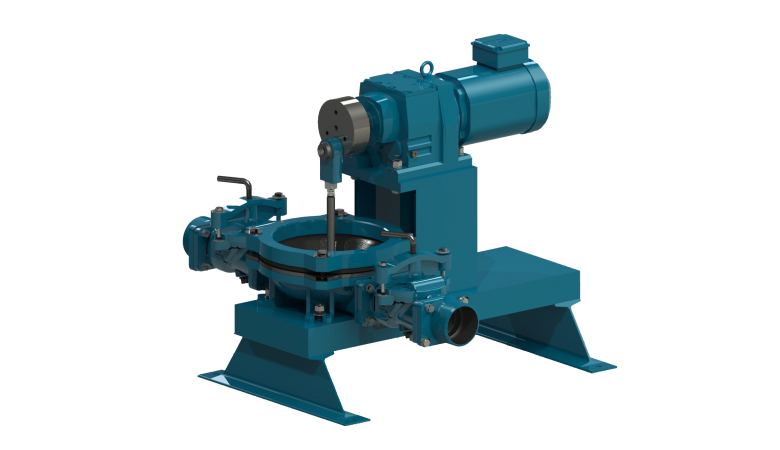

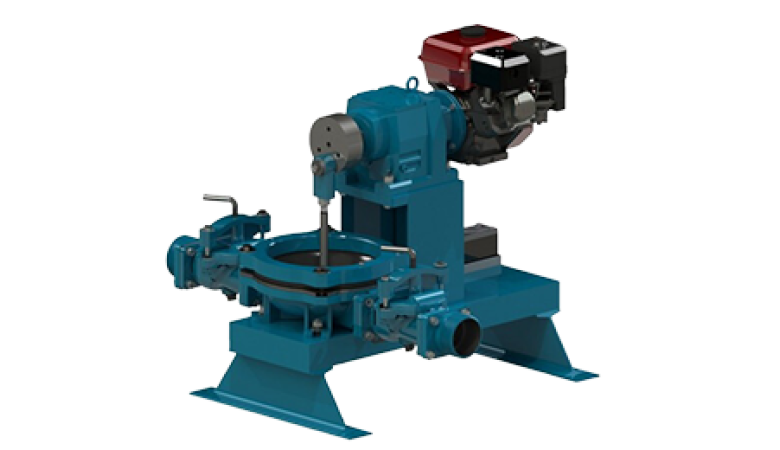

Diaphragm pumps come in four principle configurations: electric, engine, manual, air-operated or hydraulic.

Air-operated diaphragm pumps use compressed air to move the diaphragms back and forth, allowing them to operate virtually anywhere. Electric diaphragm pumps, on the other hand, are powered by an electric motor. They’re highly energy-efficient and capable of precision dosing, making them the preferred choice for some industrial applications. Similar to electric diaphragm pumps, engine pumps are driven by a motor. However, the motor in an engine pump runs on fuel rather than electricity.

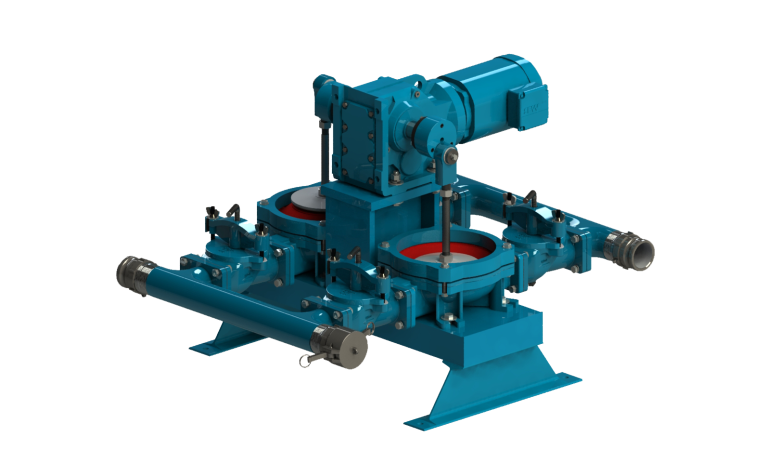

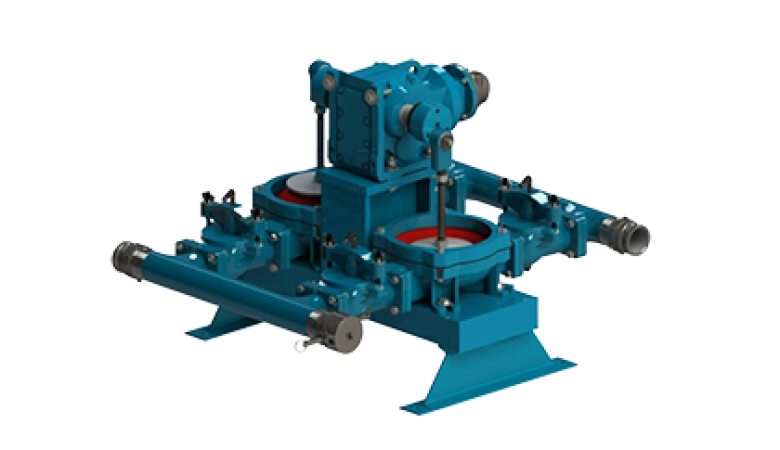

In a hydraulic pump, the diaphragms are driven by pressurized hydraulic fluid. The hydraulic fluid creates counter-pressure, which gives these pumps superior resistance to high pressures and flow rates.

Learn more about Mud Sucker 2B series & 3B series.

What kinds of fluids does a diaphragm pump transfer?

One of the main advantages of using a diaphragm pump is the incredible variety of fluids these pumps can transfer. Some of the many fluids a diaphragm pump can transfer include wastewater, mineral slurries, food and beverage products (such as milk, yogurt, syrups, fillings and sauces), non-combustible oil, paint, chemical solutions (e.g., herbicides and pesticides), resin compounds, and adhesives.

Diaphragm pumps can handle high-viscosity liquids and liquids with a high percentage of suspended solids without stalling, clogging, or sustaining damage. They’re also appropriate for use with shear-sensitive liquids.

What sizes of diaphragm pumps are available?

Diaphragm pumps are available in connection sizes ranging from 1-4 inches, with larger connection sizes being preferred for tasks where a high flow rate is required. Couplings are available to fit almost any piping arrangement.

Can I customize my diaphragm pump?

At Wastecorp, we offer comprehensive Mud Sucker brand diaphragm pump customization services. Customers can choose from multiple diaphragm pump materials and configurations, with several options available for handling highly corrosive and abrasive liquids. In some cases, customers can also select different motors, ball valves, mounting options, drive options, and more.

Are there additional accessories I can add to my pump?

Absolutely! We offer numerous accessories to extend the functionality of your pump, making it possible to use one pump for multiple applications. Most of our pumps also come with the option of ordering a spare parts kit, making routine maintenance easier and more convenient.

How do I get a quote for a diaphragm pump?

To get a quote for a diaphragm pump, navigate to the type of pump you wish to purchase and select the “Quote” or “Configure Your Own” option. If you aren’t sure what type of diaphragm pump you need or have a question about our pumps, you can use our convenient online portal to Request Information.

How do I order a diaphragm pump? What is the return policy for pumps?

To order a diaphragm pump, visit our Products page and navigate to the type of pump you wish to purchase, then click on “Quote” or “Configure Your Own.”

Due to the nature of fluid handling applications, pumps and pump parts cannot be returned after purchase. However, all of our products are covered by our standard warranty.

Where are Mud Sucker diaphragm pumps manufactured/shipped from?

Mud Sucker diaphragm pumps are one of the only pump brands designed, manufactured, and shipped exclusively in North America. By keeping production local, we can ensure superior quality control and offer enhanced customer support.

Do the pumps come with a warranty?

Yes, all Mud Sucker Diaphragm Pumps come with a limited one year warranty. Common wear items are not covered under the standard warranty. Visit our Terms and Conditions page for detailed information about our warranty policies.

Who should I contact about issues with my diaphragm pump?

You can contact us with any questions or concerns by filling out our convenient online contact form, or by calling us at 1-888-829-2783.

What are some common issues and fixes for diaphragm pumps?

Most of the time, diaphragm pumps operate smoothly – even in challenging conditions. However, worn parts or installation errors can cause performance issues or cause the pump to cease functioning altogether. Some common problems encountered during diaphragm pump operation and their solutions are as follows:

- Pump fails to cycle, or cycles once and stops. Check for worn or damaged valve balls, seats, or o-rings and replace them as needed. If the pump is in good condition, make sure the air valve is clean and unobstructed and verify that the pump is not over-pressurized. If the pump is under too much pressure, install a pressure relief valve.

- There are air bubbles in the liquid being expelled. Look for loose parts, paying close attention to the suction line, manifold and manifold seals, and O-rings. If there are no loose parts, this problem may indicate the diaphragms need replacing.

- The pump air valve freezes. This issue usually indicates there is too much water in the pump’s air supply. Take steps to reduce moisture content in the compressed air, such as by installing a dryer or filter.

- Air is leaking from the pump. Tighten the air valve cover and replace any worn gaskets.

- Fluid is leaking from the pump. Tighten the manifold bolts and inspect the seal between the manifold and seat. Replace seats and O-rings as needed.

- Pump is not achieving prime. Try reducing the air inlet pressure. If that does not work, inspect the pump’s outlets and inlets to make sure they are open and not clogged with debris. If the pump still will not prime, you may need to replace the check valve ball and seat or the manifold O-rings.

What are the best industrial applications for diaphragm pumps?

Diaphragm pumps are used across many different industries owing to their versatility, efficiency, and durability. Some of the top industrial applications for diaphragm pumps include wastewater treatment, manufacturing, food and beverage processing, agricultural spraying, building and construction, mining, and oil and gas production. Diaphragm pumps are also used in the pharmaceutical, automotive, transportation, and aerospace industries.

As well as manufacturing pumps for industrial uses, WasteCorp supplies pumps to small businesses (such as hotels, restaurants, and marinas) and provides pumps to homeowners who need them for water removal or DIY projects.

What is different about a Mud Sucker Diaphragm pump?

For over 30 years, Wastecorp has been one of the most trusted names in the pump manufacturing industry. With an emphasis on sustainability and environmental responsibility, we design pumps that prevent leaks, spills, and contamination while offering exceptional performance. Our pumps are built with premium materials, including Santoprene, Neoprene, and stainless steel, which gives them an extremely long flex-life and the ability to handle corrosive and abrasive liquids.

In addition to designing and manufacturing our pumps exclusively in North America, we offer customers an unmatched array of customization options. Unlike other manufacturers, we’ll help you select the best diaphragm pump materials for your application and work with you to design the perfect pump for your specific task and fluid handling needs. We also offer comprehensive customer support and a complete selection of diaphragm pump spare parts, making it easy to repair and maintain our Mud Sucker diaphragm pumps.